VORKUTA

CEMENT PLANT

CEMENT PLANT

Unique offer

Acquire a cement and building materials production plant

Vorkuta Cement Plant is the only enterprise in

the European Arctic producing cement and mineral products.

It is located in an area rich in limestone and clay shale deposits.

the European Arctic producing cement and mineral products.

It is located in an area rich in limestone and clay shale deposits.

Оставить заявку

на консультацию

на консультацию

Get the offer terms

Have a question?

Leave your name, phone number, and email — and we’ll get back to you shortly!

By submitting this form, you consent to the processing of your personal data in line with our privacy policy.

Interested?

Leave your name, phone number, and email — and we’ll get back to you shortly!

By submitting this form, you consent to the processing of your personal data in line with our privacy policy.

Advantages of Investing

in Cement and Building Materials Production

in Cement and Building Materials Production

Advantages of Investing in

Cement and Building Materials Production

Cement and Building Materials Production

Promising and growing cement market, especially in the Arctic

Low initial investment required to launch production

Secured raw material supply for cement and construction materials users

High added value of specialty cements

Strategic location in Russia’s Arctic Special Economic Zone provides exclusive access to key markets of the developing Trans-Arctic Transport Corridor

Business overview

Production Capacity:

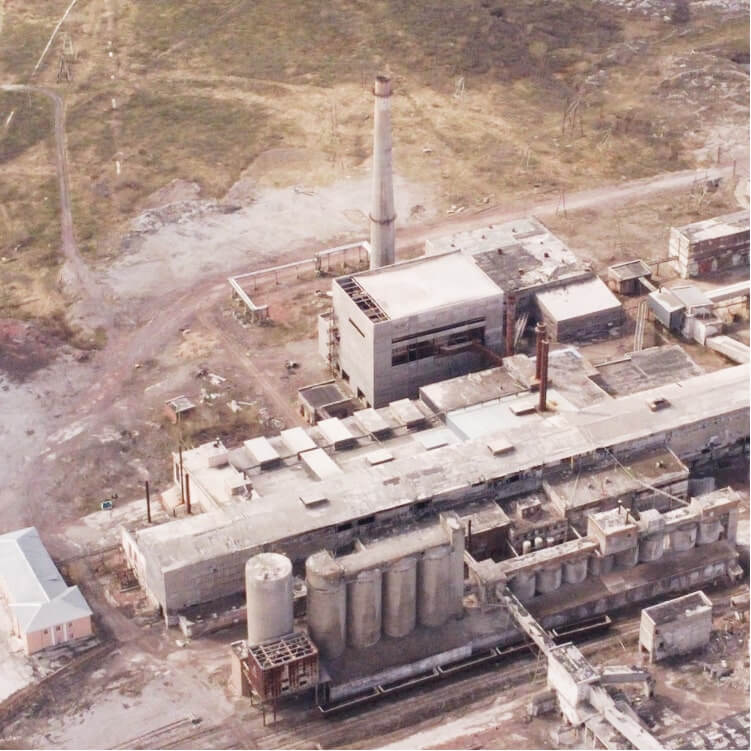

Vorkuta Cement Plant is the only enterprise in

the European Arctic producing cement and mineral products.

It is located in an area rich in limestone and clay shale deposits.

the European Arctic producing cement and mineral products.

It is located in an area rich in limestone and clay shale deposits.

Cement and Building Materials Production Plant

Location: Vorkuta City, Komi Republic, Russia

Up to 430

thousand tons

general-purpose and specialty cement for airfield and road construction

Plant Commissioned: September 15, 1950

Total plant land area: 59 160 m²

Total quarry land area: 763 638 m²

Built-up Area (Workshops and Buildings): 35 398 m²

Power Supply: 8 500 КВт

Total onsite railway length: 2 374 m

Ownership: Privately owned, single proprietor, no encumbrances

Over 300

thousand tons

limestone gravel and artificial sand

thousand tons

Up to 20

limestone flour

Up to 50

thousand tons

hydrophobic inert dust

1

2

3

4

Up to 50

thousand tons

activated mineral powder

Become the owner of

a high-capacity production facility

a high-capacity production facility

5

Cement Market Outlook

1...Large-scale Arctic projects with unprecedented investment in strategic infrastructure

Learn more

Learn more

3...Cement plants as highly efficient waste utilization facilities for a wide range of waste, including MSW and used tires.

Learn more

Maximize Value by 2035

2...Significant backlog of cement demand in Russia: the national strategy for industrial development sets an annual consumption target of 90 million tons of cement by 2035.

Cement Market

to Grow

up to 35%

by 2035

to Grow

up to 35%

by 2035

Outlook №1

The Russian Arctic Zone and the Trans-Arctic Transport Corridor: a Key Strategic Development Area

By 2035, the Government of the Russian Federation, in cooperation with VEB.RF, the Far East and Arctic Development Corporation, and private investors, plans to implement large-scale infrastructure projects totaling more than 3 trillion rubles. These include:

• Implementation of the master plan for the city of Vorkuta, which involves the construction of a modern gas-chemical complex, large-scale airport reconstruction, and the establishment of a high-tech medical center.

• Development of the Northern Sea Route, including the construction and modernization of the ports of Sabetta, Dudinka, Igarka, Dikson, Tiksi, and Pevek.

• The Northern Latitudinal Railway Project, which includes construction of a railway bridge over the Ob River and new railway sections connecting key economic hubs in the North, including Norilsk and Sabetta.

These projects form part of the official Arctic Zone Development Strategy and Russia’s National Security Framework through 2035, approved by the President of the Russian Federation. They open vast opportunities for business and give a strong boost to regional economic growth — significantly increasing demand for construction materials, including cement.

By 2035, the Government of the Russian Federation, in cooperation with VEB.RF, the Far East and Arctic Development Corporation, and private investors, plans to implement large-scale infrastructure projects totaling more than 3 trillion rubles. These include:

• Implementation of the master plan for the city of Vorkuta, which involves the construction of a modern gas-chemical complex, large-scale airport reconstruction, and the establishment of a high-tech medical center.

• Development of the Northern Sea Route, including the construction and modernization of the ports of Sabetta, Dudinka, Igarka, Dikson, Tiksi, and Pevek.

• The Northern Latitudinal Railway Project, which includes construction of a railway bridge over the Ob River and new railway sections connecting key economic hubs in the North, including Norilsk and Sabetta.

These projects form part of the official Arctic Zone Development Strategy and Russia’s National Security Framework through 2035, approved by the President of the Russian Federation. They open vast opportunities for business and give a strong boost to regional economic growth — significantly increasing demand for construction materials, including cement.

Outlook №2

Significant Deferred Demand for Cement in Russia.

According to the Russian Federation’s Industrial Development Strategy through 2035, annual cement consumption is projected to reach 90 million tons.

Meanwhile, actual cement consumption in 2024 totaled 67 million tons, highlighting a substantial gap and indicating strong future growth potential in the domestic market.

According to the Russian Federation’s Industrial Development Strategy through 2035, annual cement consumption is projected to reach 90 million tons.

Meanwhile, actual cement consumption in 2024 totaled 67 million tons, highlighting a substantial gap and indicating strong future growth potential in the domestic market.

Outlook №3

Cement Plants as High-Efficiency Waste Utilization Facilities.

Cement plants are among the most effective industrial facilities for processing a wide range of waste, including municipal solid waste (MSW) and used tires.

As part of Russia’s national project “Environmental Well-Being”, a circular economy is being established — where waste is increasingly treated as a valuable resource. By 2030, 100% of MSW in the country is expected to be sorted, with at least 25% recycled as secondary raw materials.

Thanks to “2-in-1” waste utilization technology, processed waste can be used in cement kilns as alternative fuel, reducing reliance on conventional coal.

In the European Union, the average substitution rate of conventional fuel with alternative fuels in cement production has already reached 40%.

Cement plants are among the most effective industrial facilities for processing a wide range of waste, including municipal solid waste (MSW) and used tires.

As part of Russia’s national project “Environmental Well-Being”, a circular economy is being established — where waste is increasingly treated as a valuable resource. By 2030, 100% of MSW in the country is expected to be sorted, with at least 25% recycled as secondary raw materials.

Thanks to “2-in-1” waste utilization technology, processed waste can be used in cement kilns as alternative fuel, reducing reliance on conventional coal.

In the European Union, the average substitution rate of conventional fuel with alternative fuels in cement production has already reached 40%.

Production Flowchart

Wet Process for portland cement production

Raw Materials: Limestone, Clay Shale

Raw Materials: Limestone, Clay Shale

Active Mineral Additives

gypsum, fly ash, burnt rock

Kiln Fuel

bituminous coal grade GZhO OMSH

Potential for Production Gasification

The plant includes three cement production lines

Get the offer terms

Main Equipment of the Plant

3 Clinker

Rotary Kilns

Rotary Kilns

diameter - 3.6 meters,

length - 88 meters

length - 88 meters

3 Coal

Mills

Mills

13 Silos

11,000 tons

total capacity

total capacity

Cement Mills

Raw Mills

4 units

2 units

Packing Line

into soft one-ton Big-Bag containers and 50 kg valve paper bags

IN ADDITION,

Crushed Stone Sorting Line

SPECO

Jaw Crusher

Jaw Crusher

300 tons/hour

Cranes

Quarry Excavators

Dump Trucks

Rail Rolling Stock for Intra-City Transport

Other Transport Equipment

Extensive Silo Infrastructure

The plant is equipped with 13 silos. This large-scale silo infrastructure — unusual for a facility of this production size — enables the manufacturing of a wide range of high-value specialty cements, including oil well cements, which are extensively used in the oil, gas, and nuclear industries.

Incentives for Residents of the Russian Arctic Zone

The plant is located in a Special Economic Zone (SEZ) within the Russian Arctic, offering significant tax benefits and administrative preferences. These incentives include:

• Reduced mineral extraction tax (MET)

• Lower corporate income tax

• Tax relief on land and property

• Subsidized social insurance contributions

• Reduced mineral extraction tax (MET)

• Lower corporate income tax

• Tax relief on land and property

• Subsidized social insurance contributions

Great Logistical Efficiency

The plant’s geographic location is advantageous for major cement consumers in the Northwestern and Ural Federal Districts (central Russian Arctic), including the oil and gas sector of the Komi Republic and Yamalo-Nenets Autonomous District, as well as customers in Kirov Oblast.

Strategic Development of the Arctic

The development of the Arctic Zone is a top priority for the Russian Federation. In the coming years, the region will see the implementation of major federal infrastructure projects aimed at expanding the Trans-Arctic Transport Corridor, with total investments exceeding 3 trillion rubles. These initiatives include the development of the Northern Sea Route, the Northern Latitudinal Railway, and the execution of Vorkuta’s master plan — the easternmost city in Europe, located just 140 km from the coast of the Arctic Ocean.

The government and leading companies are actively investing in the region, recognizing the Arctic’s strategic importance in the context of global economic transformation. Global economic trends, climate change, and global warming are opening new opportunities for logistics, resource development, and infrastructure expansion — all of which are driving steady growth in demand for cement.

The government and leading companies are actively investing in the region, recognizing the Arctic’s strategic importance in the context of global economic transformation. Global economic trends, climate change, and global warming are opening new opportunities for logistics, resource development, and infrastructure expansion — all of which are driving steady growth in demand for cement.

Advantages of Using Waste in Cement Production

The use of industrial and municipal waste as alternative fuel in cement production is a key strategy that offers multiple benefits:

• Reduced energy costs — energy accounts for 50–57% of total production costs. By replacing part of the conventional fuel with secondary fuel derived from municipal solid waste (MSW) and used tires (commonly known as Refuse-Derived Fuel, RDF), significant savings can be achieved.

• Additional revenue from waste disposal and utilization.

• Eligibility for environmental tax benefits through the use of Best Available Technologies (BAT), as outlined in Federal Law No. 7-FZ of January 10, 2002 “On Environmental Protection.”

• Reduced energy costs — energy accounts for 50–57% of total production costs. By replacing part of the conventional fuel with secondary fuel derived from municipal solid waste (MSW) and used tires (commonly known as Refuse-Derived Fuel, RDF), significant savings can be achieved.

• Additional revenue from waste disposal and utilization.

• Eligibility for environmental tax benefits through the use of Best Available Technologies (BAT), as outlined in Federal Law No. 7-FZ of January 10, 2002 “On Environmental Protection.”

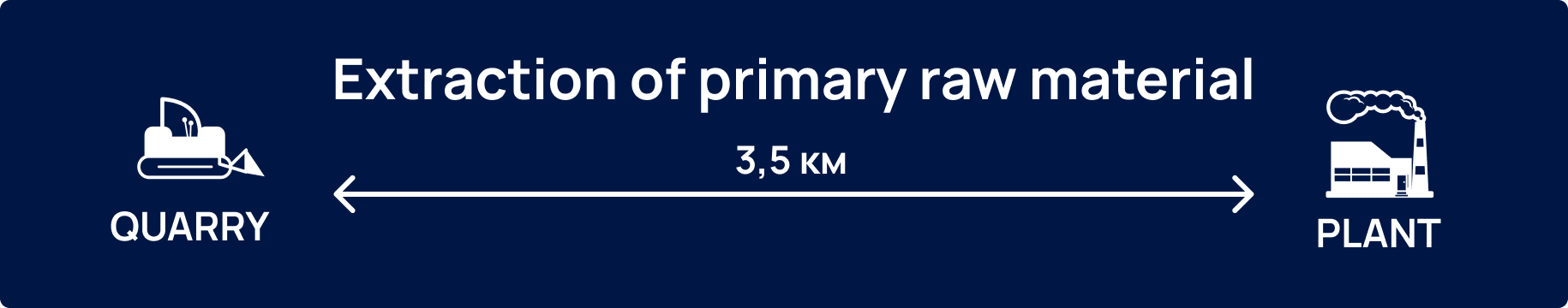

3,5 km

High-quality limestone ensures the production of cement with superior characteristics

Proximity to a Unique Raw Material Base

Strengths and Potential of Vorkuta Cement Plant:

Become the owner

of a unique

production facility

of a unique

production facility

Мы используем cookie-файлы, чтобы обеспечить вам лучшую навигацию по нашему веб-сайту. Если вы продолжите навигацию, вы дадите разрешение на использование cookie-файлов

Хорошо